ZeroF Consortium Meets for Its Final Project Meeting

18–20 November 2025 in Terrassa & Barcelona

With just one month remaining, the twelve ZeroF partners met for their final gathering at Leitat’s facilities in Terrassa, Spain. Over three productive days, the consortium reviewed progress, aligned on remaining tasks, and prepared for the public Stakeholder Event. Held on 20 November in Barcelona, the hybrid event brought together 80 experts from research, industry, and innovation to showcase the project’s achievements and discuss the next steps toward PFAS-free solutions in key sectors such as packaging and textiles.

Day 1: Final Results & Preparing ZeroF’s Legacy

The day of presentations and interactive sessions began with a welcome from host partner Leitat and project coordinator Miika Nikinmaa (VTT). They recapped the past three years, highlighted the strong collaboration among partners, and introduced the day’s agenda, promising an engaging programme that would showcase all key results and prepare for the project’s closing and reporting.

PFAS-free Coatings for Upholstery Textiles

Fraunhofer ISC, Leitat, E.Cima, and Tèxtils.CAT presented the final advances in PFAS-free textile coatings and their application on different fabrics, including the presentation of the final prototype – a small sofa cushion coated with ZeroF’s PFAS-free formulation. Focused on upholstery fabrics, where spill resistance is essential, Fraunhofer’s ORMOCER® hybrid coatings combine inorganic and organic components to provide strong water repellency and moderate oil repellency. Fabrics treated with ZeroF’s coatings resist water and common soils such as coffee or oil, although they do not yet achieve the extreme oil repellency of traditional fluorinated treatments.

Laboratory and semi-industrial trials demonstrated that these coatings can be applied using standard industry equipment, though further work is needed to optimise stability, abrasion resistance, and long-term wash performance. The project showed that PFAS-free performance is achievable for many indoor textiles, provided that industry standards are adjusted to reflect realistic, non-fluorinated benchmarks, particularly regarding oil repellency.

PFAS-free Coatings for Packaging Solutions

The packaging partners VTT, Kemira and Yangi shared progress on developing PFAS-free, bio-based coatings for moulded fibre and paper that resist grease and moisture. For food packaging, ZeroF created coatings from modified natural materials such as cellulose and starch combined with long-chain fatty acids (CeFAE materials). These coatings can be applied as water-based dispersions or powders and provide strong water and grease barriers on flat boards as well as on 3D-shaped fibre products, including trays, cups and other packaging prototypes, meeting or exceeding internal barrier performance targets.

Pilot-scale production in standard reactors showed that industrial-scale quantities are achievable. The coated 3D products performed well under typical use conditions and were partially compostable. Further work would now be required to optimise recyclability, ensure safe food contact, and minimise residues at the end of life, in line with upcoming EU packaging and food contact material regulations.

From Research to Real Impact

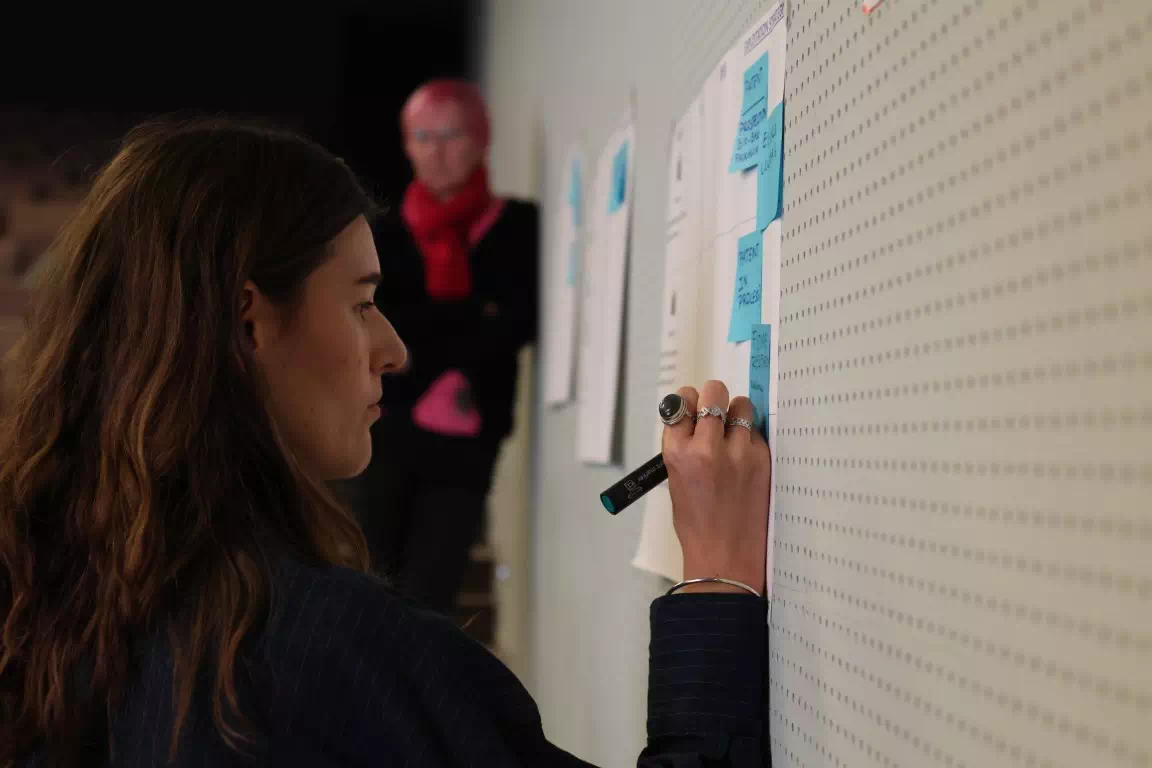

In the afternoon, partners reviewed ZeroF’s results, both individually and jointly, discussing how to build on them and continue making an impact after the project ends. An interactive workshop led by LGI highlighted each partner’s achievements, the consortium’s overall contributions to PFAS-free solutions in textiles and packaging, and the most promising paths for transferring these innovations to industry. The session also reviewed the project’s key outreach successes and outlined the roadmap ahead, including further testing, scale-up, and regulatory alignment as ZeroF concludes.

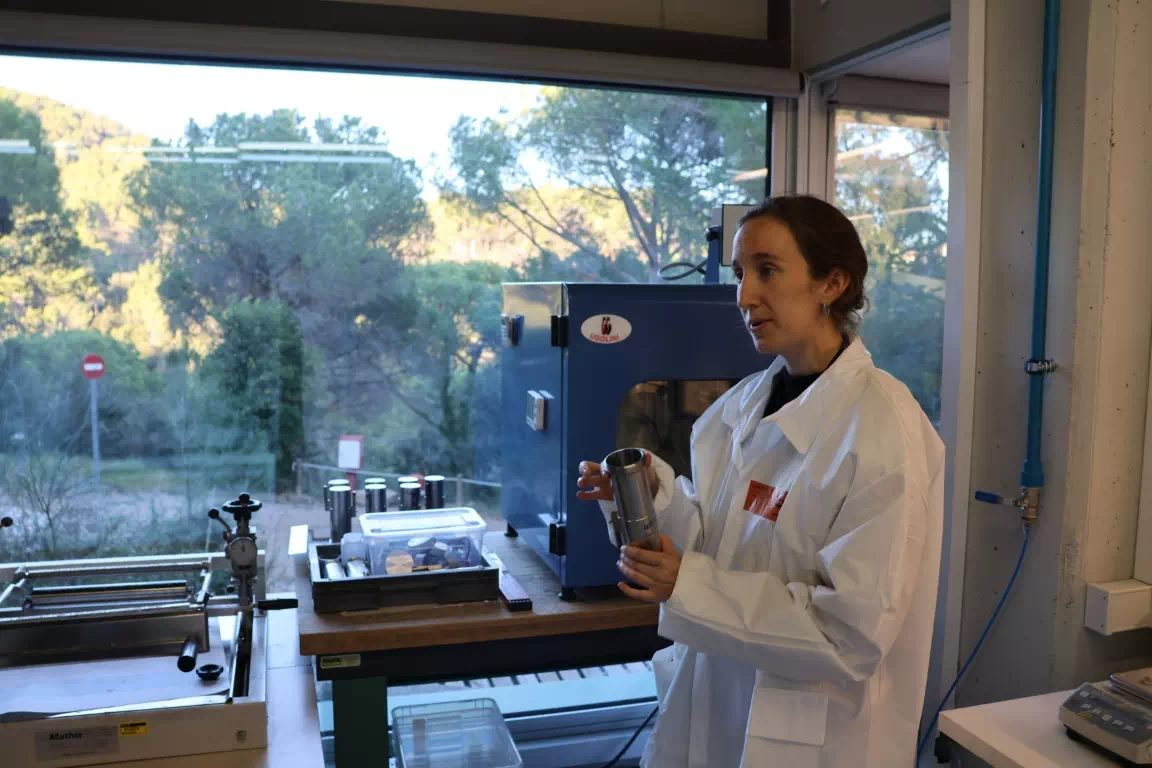

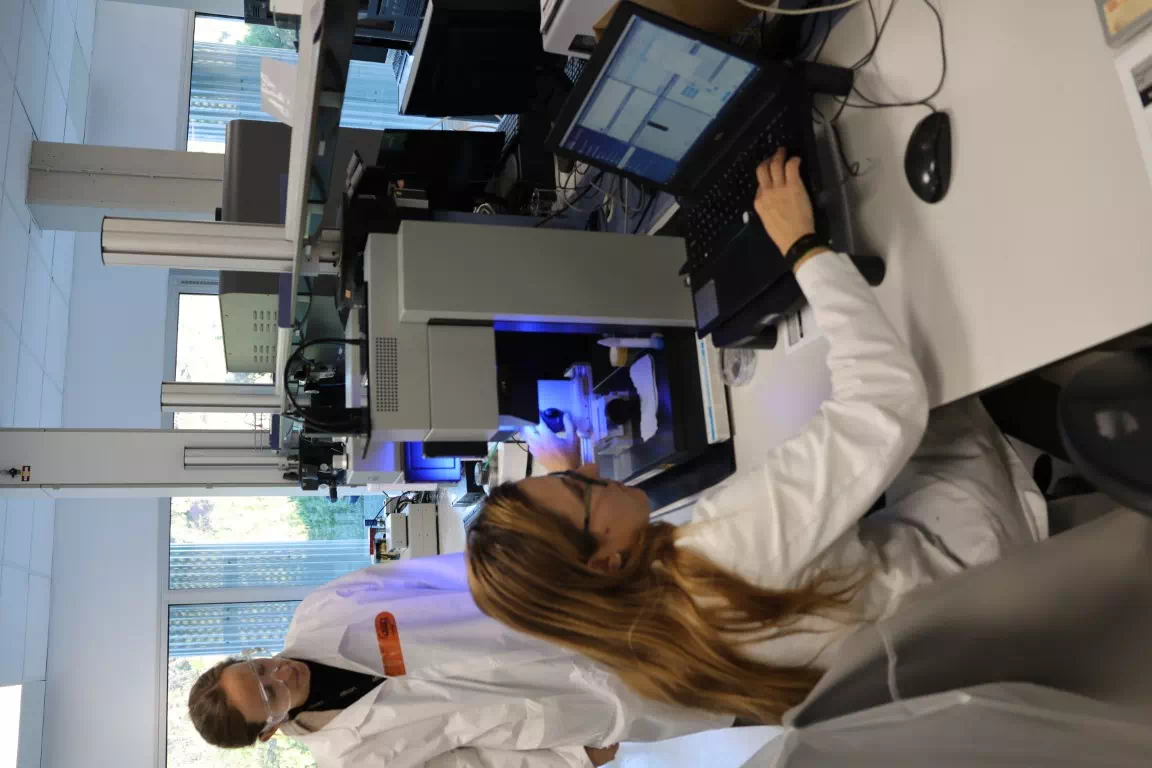

The day ended with a tour of Leitat’s laboratories in Terrassa, providing partners with an overview of the facilities and a closer look at the equipment used for ZeroF’s textile work.

Day 2: Consumers, Sustainability, Impact & Modelling

The second day opened with the General Assembly meeting, followed by presentations on topics such as consumer expectations, ensuring safety and sustainability, and modelling activities.

Understanding Consumer Expectations

VTT, supported by Leitat, surveyed 1,500 consumers in Finland, France, Spain, and Luxembourg about their knowledge of PFAS and willingness to adopt PFAS-free alternatives. 62% respondents had never heard of PFAS. Once informed, they showed a strong preference for PFAS-free products, especially in food packaging and textiles, and around one third are already actively seeking these alternatives.

Consumers expect clear labelling, simple proof of safety, and assurance that products have been independently tested. Willingness to pay more is mostly limited to highly engaged groups, while wider adoption depends on PFAS-free products becoming the standard. The findings show the importance of regulation, standards, and public procurement in supporting market uptake.

Ensuring Safety & Sustainability

ZeroF partners, including the Luxembourg Institute of Science and Technology, TEMAS Solutions, IDEA.consult, and LGI, applied the Safe and Sustainable by Design (SSbD) approach throughout the development of ZeroF coatings, ensuring that safety, environmental responsibility, and economic viability were considered at every stage. This continuous application of SSbD, supported by modelling activities from IDEA.consult and the University of Bologna, helped optimise formulations and improve understanding of product performance.

As a result, around 20 hazardous substances were substituted, reduced, or planned for phase-out across formulations and processes, while process improvements reduced solvent use and energy consumption. Environmental assessments showed that PFAS-free packaging prototypes generally have lower overall impacts than PFAS-coated references, and textile prototypes achieve significant reductions in PFAS emissions, though other impact categories show mixed results, highlighting trade-offs that policymakers must consider when setting future standards.

Assessing ZeroF’s Impact

LGI presented a series of analyses as part of the final ZeroF impact study, evaluating the project’s outcomes and potential future opportunities. The work included mapping key stakeholders, assessing alternative materials, modelling current and potential new value chains, analysing external trends using political, economic, social, technological, environmental, and legal (PESTEL) factors, and examining the strengths, weaknesses, opportunities, and threats (SWOT) of the proposed solutions. The study also outlined next steps for continuing the impact of ZeroF’s results beyond the project. The afternoon was then dedicated to preparing for the next day’s public Stakeholder Event.

Day 3: Engaging Stakeholders & Sharing ZeroF’s Innovations

On 20 November 2025, the ZeroF project held its final stakeholder event, “PFAS FREE FUTURE – Safe & Sustainable Alternatives for Packaging & Textile,” at the Cambra de Comerç de Barcelona. The hybrid event gathered around 80 participants, both in person and online, including representatives from research, industry, and public authorities.

Ruth Garcia (Leitat) and Miika Nikinmaa (VTT) opened the event by welcoming all participants, underlining the urgency of finding PFAS alternatives, and introducing ZeroF and its objectives to the audience.

The event programme featured a series of presentations and discussions covering the latest in PFAS-free innovations. Blanca Suarez-Merino (TEMAS Solutions) opened with an overview of the evolving PFAS policy landscape. ZeroF’s textile innovations were presented by Diana Lau (Fraunhofer ISC) and Ruth Garcia (Leitat), followed by VTT’s showcase of food packaging solutions. Tom Tamlander (VTT) and Eddo Da Silva Rosa (LGI) explored consumer understanding and strategies to raise public awareness.

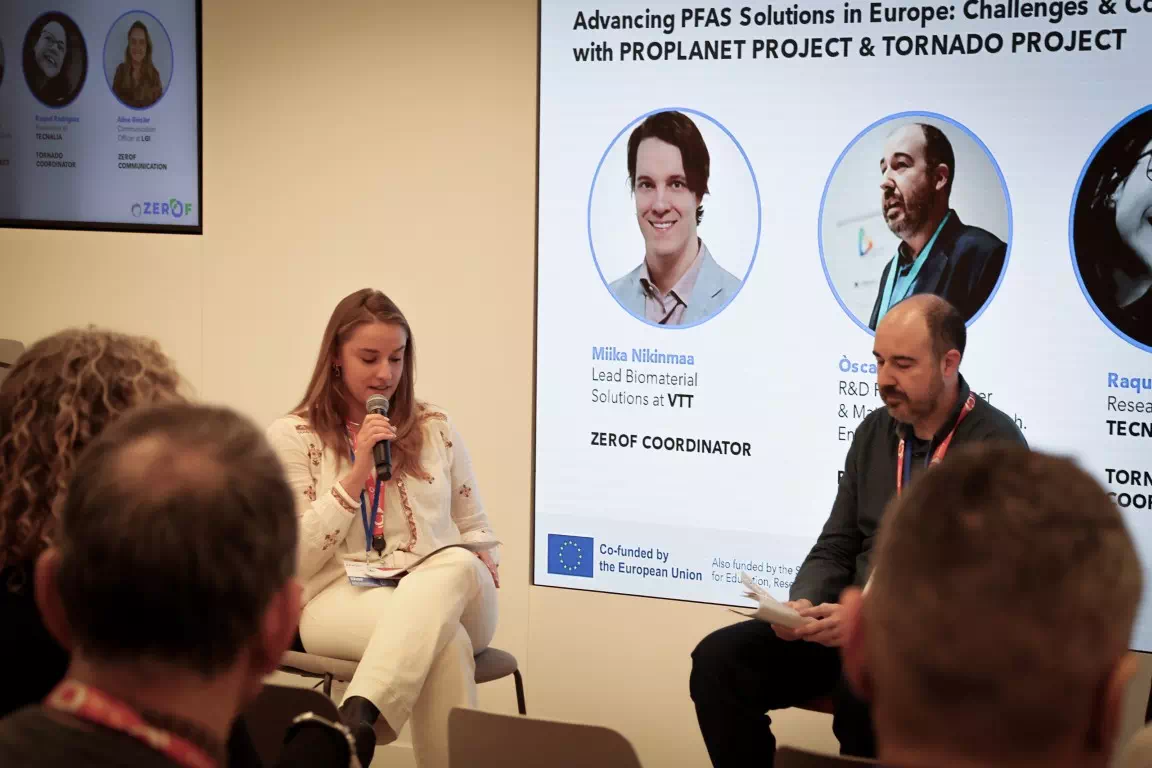

A joint panel with sister projects PROPLANET and TORNADO, moderated by Alina Giesler (LGI), highlighted shared challenges and opportunities, featuring Miika Nikinmaa (VTT), Òscar Calvo (AITEX & PROPLANET), and Raquel Rodríguez (Tecnalia & TORNADO). Lessons from applying the Safe-and-Sustainable-by-Design (SSbD) framework were presented by Panagiotis Isigonis (LIST), Elise Morel (TEMAS Solutions) on safety and hazard assessment including computational safety tools, Federico Busio (LIST) on environmental assessment, and Imad Audi (LGI) on economic assessment.

The final panel discussion focused on scaling PFAS-free solutions from lab to industry, featuring textile perspectives from Estel Sarrau (E.Cima) and Marta Casadesús (Tèxtils.CAT), packaging insights from Mårten Alkhagen (Yangi) and Tarja Turkki (Kemira), and moderated by Hille Helkiö (VTT).

The event concluded with remarks from the project coordinator Miika Nikinmaa (VTT) emphasising the excellent work done in the ZeroF project, as well as the importance of collaboration, transparency, and continued innovation as Europe moves toward PFAS-free materials.

Throughout the day, several themes emerged:

- Regulation is accelerating new rules for chemicals, food-contact materials, packaging and textiles will tighten requirements for PFAS, recyclability, and overall safety.

- Compliance requires strong data: companies will need robust documentation of safety, migration, performance and non-intentionally added substances (NIAS).

- Standards need updating: many current test methods were designed for PFAS-based materials and do not reflect the realistic performance of PFAS-free alternatives.

- Collaboration is essential: transitioning away from PFAS requires coordinated action among researchers, industry, regulators and consumers.

Looking Ahead: The Final Month of ZeroF

As the project enters its final month, partners are now focused on:

- completing reporting and final deliverables

- strengthening exploitation strategies

- finalising some last experiments giving key insights into the developed coatings

With strong technical results, safety and sustainability assessments, and clear pathways for impact, ZeroF is well placed to contribute to Europe’s transition toward PFAS-free materials in packaging and textiles.

WANT TO LEARN MORE? For anyone who missed the final event or wants to review it, the slides are available here: